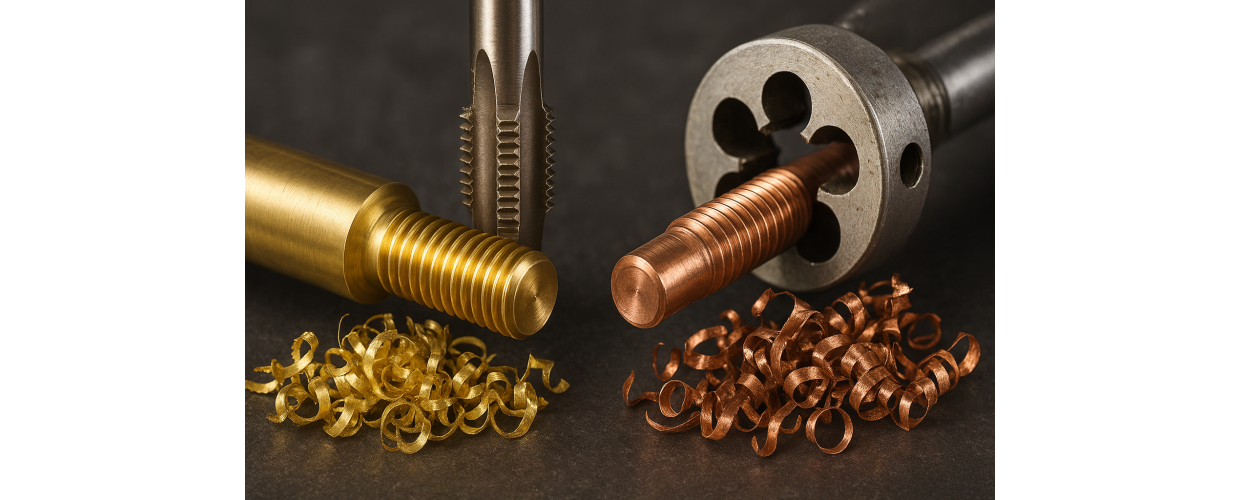

When you thread brass or copper, does it end up with torn threads or a rough finish? It is a common problem among machinists. Although these metals are soft, they aren’t easy to work with. In fact, their unique properties make threading a challenge. Let’s understand these challenges and their solutions. Why soft metals don’t thread like you expect Many assume that since copper and brass are soft, they should cut like butter. That’s not the case. Unlike steel, these metals don’t shear cleanly. Instead, they deform under pressure. Push too hard, and the material moves rather than cuts. This results in rounded, weak threads. Another issue is the chip formation. Harder metals break into small, manageable chips. Copper and brass, on the other hand, tend to create long, stringy chips. If you don’t control them, they clog the tool, heat up the workpiece, and damage the threads. Work hardening in copper Copper doesn’t just stay soft. It gets harder the more you work it. Every pass of a threading tool adds stress to the material, which makes it tougher and less cooperative. This gives uneven threads, excessive tool wear. Heat is also a problem. Friction during threading builds up temperature fast. If copper gets too hot, it hardens even more. Now, instead of cutting smoothly, the tool scrapes and tears the metal. A good technique and proper lubrication prevents this. Why brass loves to grab and tear Brass comes in different grades, and some are worse than others for threading. The higher the zinc content, the more likely it is to grab, tear, or chip unpredictably. Some machinists describe it as “sticky.” One second, it cuts fine. Next, it’s seizing the tool. Brass also tends to gum up cutting edges. As the tool moves, small bits of brass weld themselves to the cutting surface. This ruins the finish and makes threading even harder. That’s why it is important to choose the right brass alloy and cutting strategy. Choose the right cutting fluid Cutting fluid not only reduce friction, it also keeps the workpiece cool, clears chips, and improves thread quality. But not all fluids work the same way. Too much oil can make things worse. It creates a slick surface, making it harder for the tool to bite into the metal. Too little, and you’ll get excessive heat and tool wear. For threading brass, a light oil works best. For copper, a heavier tapping fluid helps prevent work hardening. Different tools for different materials Different threadings tools are available for different purposes. Standard taps and dies are designed for steel. They don’t always work well on soft metals. If the cutting angles are too aggressive, they dig too much. Too shallow, and they rub instead of cutting. For brass, a high rake angle and polished surface prevent tearing. Copper needs a sharper cutting edge with a slightly lower rake to avoid deformation. Modifying off-the-shelf tools can make a big difference. Hand threading vs machine threading Hand threading sounds simple, but it’s tricky with these metals. The uneven pressure of manual threading easily distorts soft materials. If the die isn’t perfectly square, the first few threads will be crooked, and ruin the whole job. Machine threading offers better control, but only if the feed rate and speed are right. Go too fast, and you risk galling. Too slow, and the metal work-hardens. CNC threading needs fine-tuned settings. Even slight adjustments can change the outcome. How to prevent galling and thread deformation Galling is a major problem when threading copper and brass. It happens when the metal sticks to the tool, creating rough, damaged threads. Once galling starts, it’s hard to stop. Prevention is the only real solution. Surface treatments like light oil coatings help. So does reducing friction with proper tool selection. In some cases, pre-threading annealing softens the metal slightly, and makes it easier to cut clean threads. Fix a bad thread without starting over Threading mistakes happen. But not every bad thread needs to be scrapped. There are ways to fix them. For minor damage, a thread chaser can clean up the edges. If the threads are deeper but still salvageable, a thread insert can restore strength. But if the threads are completely deformed, there’s no shortcut. You’ll need to cut them off and start fresh. Knowing when to fix and when to redo saves time and material. Conclusion Threading copper and brass is not as straightforward as it seems. These metals behave differently under pressure, heat, and cutting forces. If you treat them like steel, you’ll run into problems. Use the right tools. Control your cutting speed. Choose the right lubricant. And most importantly, understand how these metals react during threading.