Thread cutting is normally known as nuts and bolts connections and the profile shape of the thread varies according to applications. Thread cuts are manufactured through chip forming or chipless processes and can have the following functions:

Screw thread – the most commonly used in screw, nuts and bolts connections. Triangular threadform is most common.

Rotation thread – is used where force and rotation is applied as when using screw presses, lead spindles, measuring spindles and valve spindles. Here, the trapezoidal threadform is most common.

Thread seals – are used in pneumatic and hydraulic systems. It is often external conical threads that are fastened with internal cylindrical threads. Here, the triangular threadform is most commonly used.

All threads can be customized with right hand or left hand fittings.

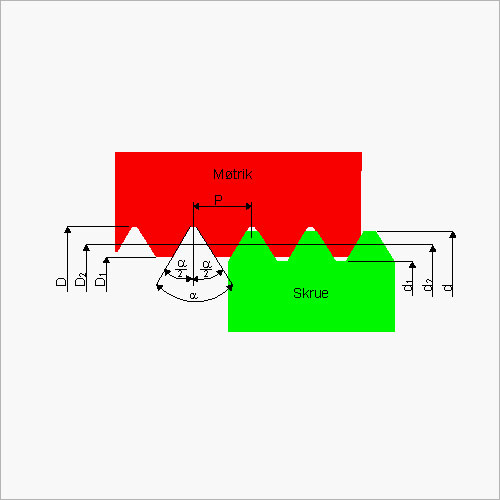

A thread cut is calculated by the following measurements:

(Møtrik = nut, skrue = screw)

Nut measurements. Screw measurements:

D = Outside diameter d = Outside diameter

D2 = pitch diameter d2 = pitch diameter

D1 = Inside diameter d1 = Inside diameter

P = pitch P = pitch

= thread angle = thread angle

When measuring thread, the most interesting measurement is:

D2 – pitch diameter or d2 – pitch diameter

P - pitch

- thread angle

Inside and outside diameters are usually not problematic.

Source: www.fagteori.dk